Manufacturing & Subcontracting For Modern Businesses- The Need

Both small businesses and large enterprises must manage production, coordinate subcontractors, and track every component in the production cycle. Effective management boosts productivity, reduces costs, and enhances customer satisfaction. GETPOS, our ERP-POS system, addresses these needs by integrating all aspects of manufacturing and subcontracting into a single platform.

GETPOS - Cloud Based POS Solution For

Manufacturing & Subcontracting

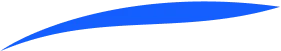

Bill of Materials

Manage to Production

Efficiently manage your production components with our comprehensive Bill of Materials feature. Track raw materials, components, and assemblies with ease, ensuring every production order is accurate and complete. This helps in reducing errors, saving time, and minimizing costs.

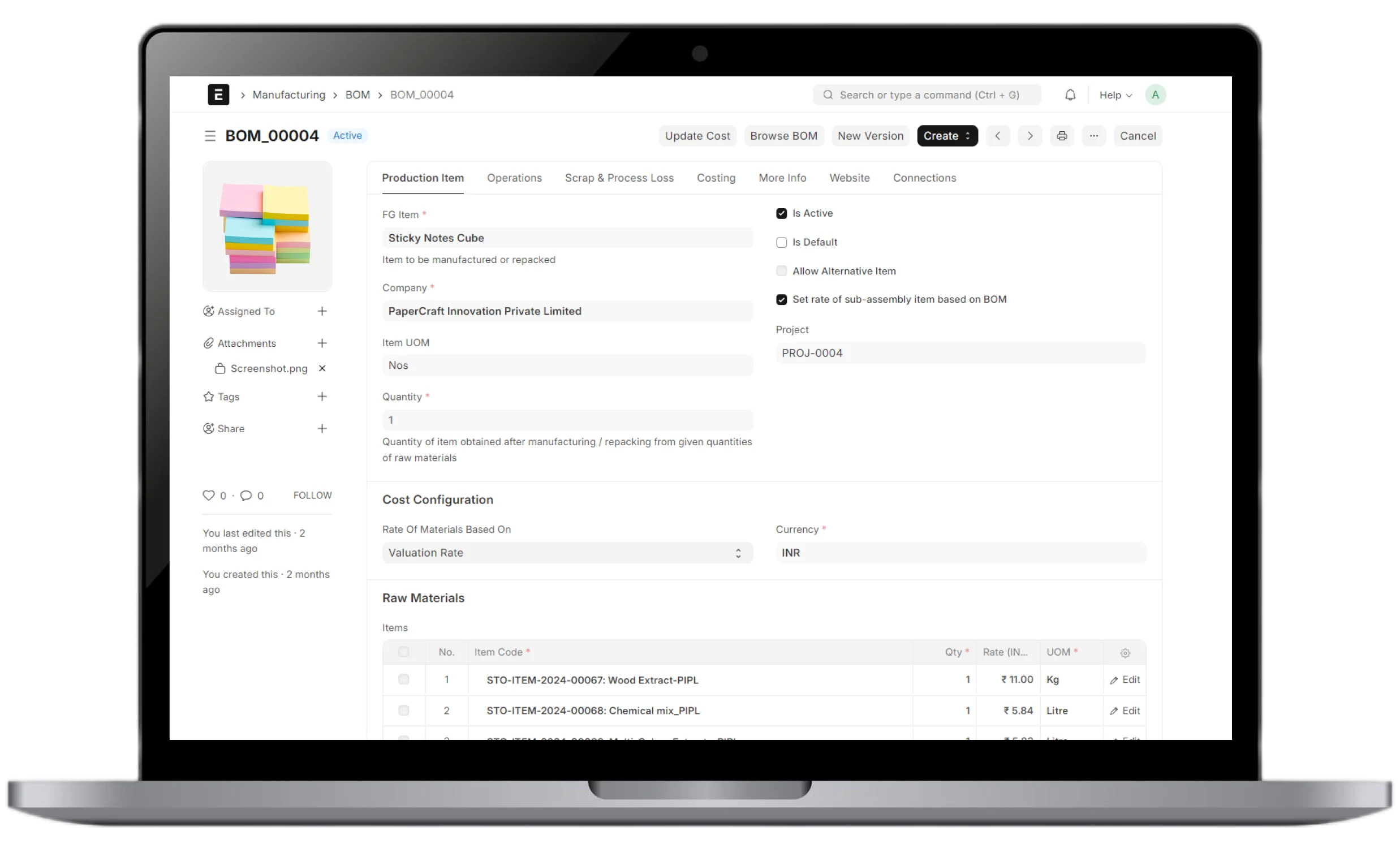

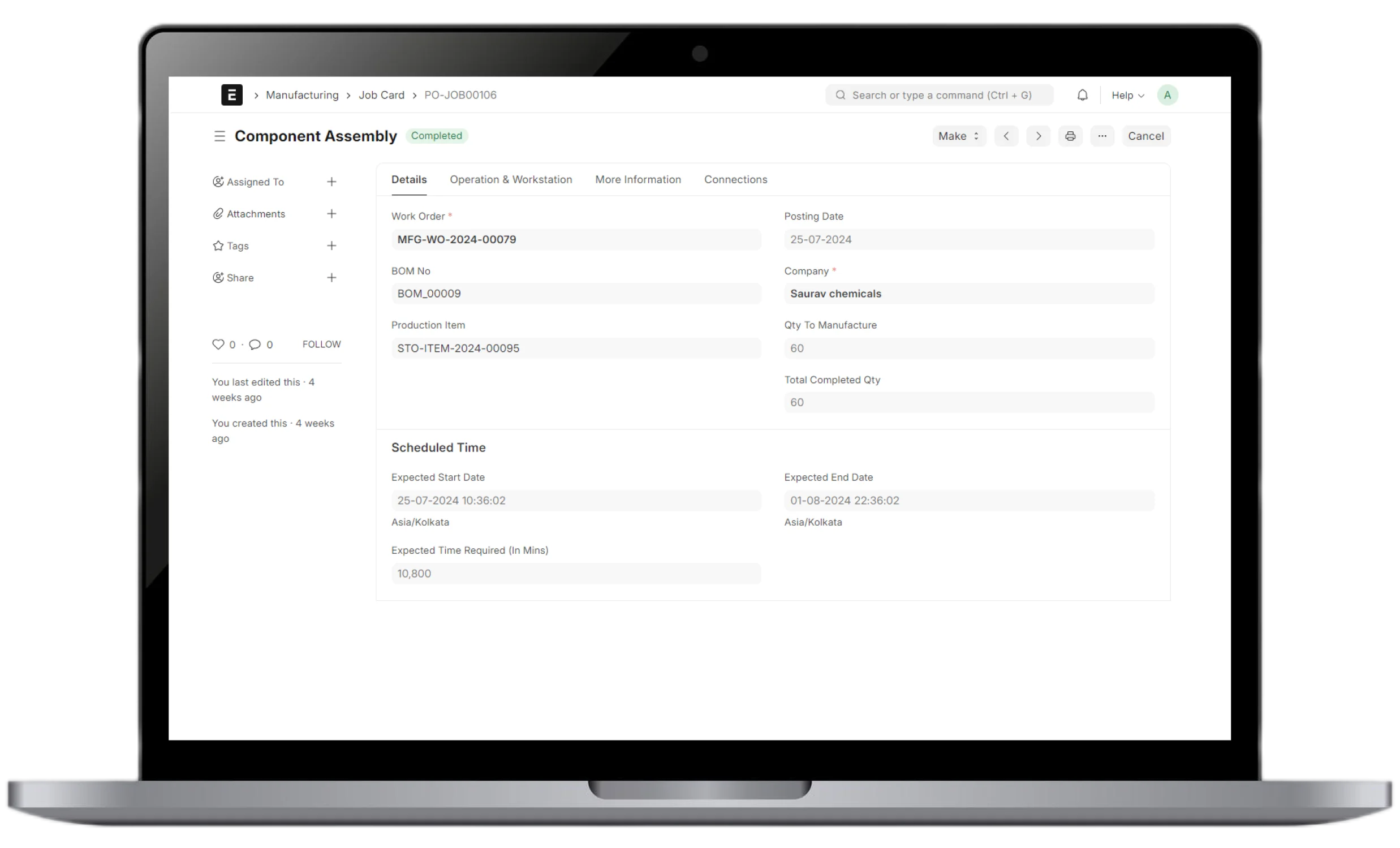

Work Order

Monitor to Progress

Our Work Order feature enables you to create, manage, and monitor work orders seamlessly. Assign tasks, set deadlines, and track progress in real-time. This ensures that every job is completed on time, within budget, and to the required standards.

Manufacturers

Make To order

For businesses that operate on a Make to Order basis, our system provides the tools to manage customer-specific production orders efficiently. From order receipt to final delivery, every step is tracked, ensuring customer satisfaction and operational efficiency.

Manufacturers

Engineer to order

Engineer to Order manufacturing requires precise coordination and customization. GETPOS supports this with detailed tracking and management features, ensuring that every custom order meets client specifications and is delivered on time.

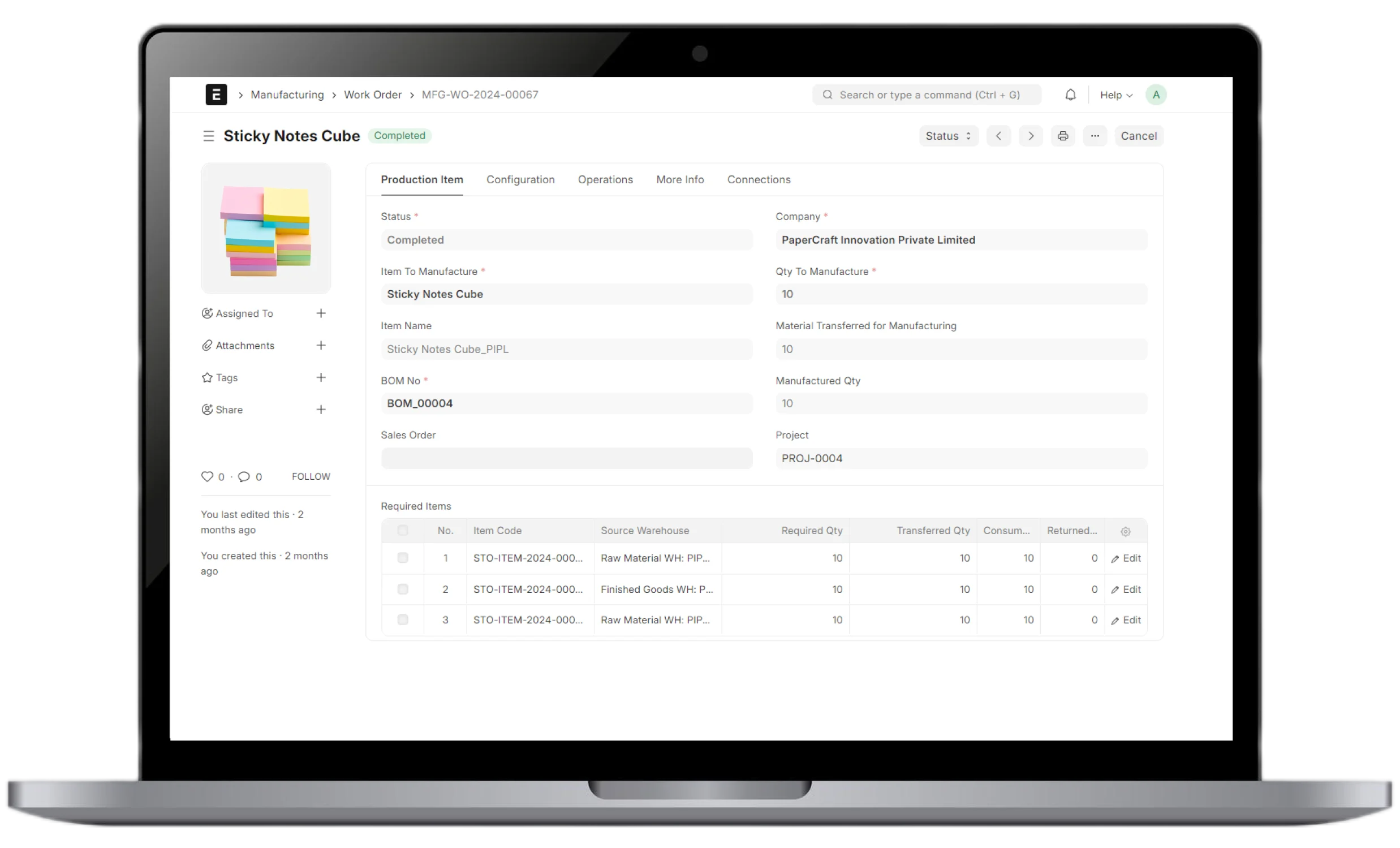

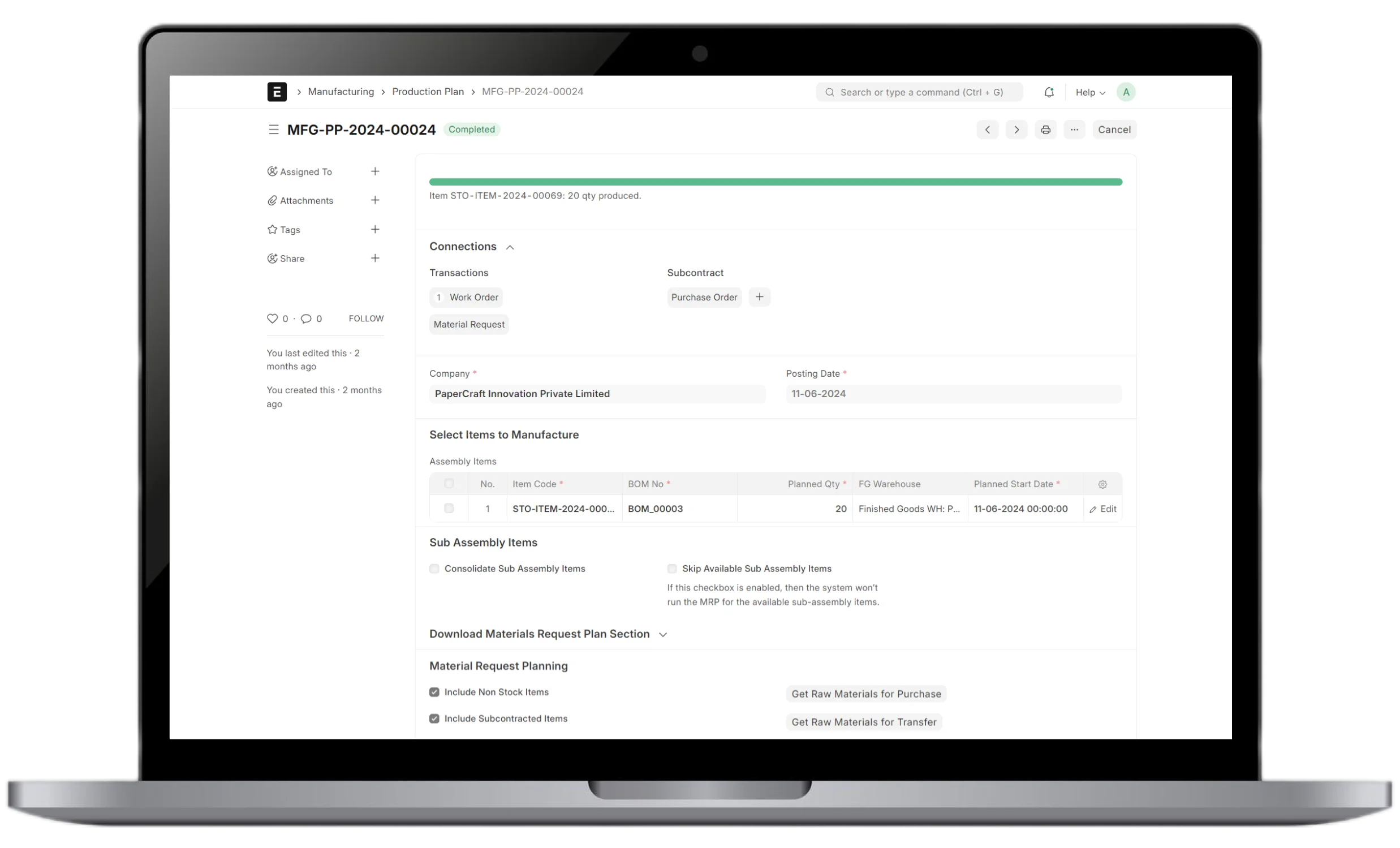

Production Plan

Schedule to allocate

Plan production schedules with our Production Plan feature. Allocate resources, set timelines, and ensure that your production processes are aligned with your business goals. This feature helps in maximizing efficiency, reducing downtime, and meeting production targets consistently.

jOIN US

Your Success, Our GETPOS!

Our ERP-POS system is designed to meet the unique needs of your business, providing the tools and features necessary to thrive in a competitive market. Join us today and take the first step towards manageable manufacturing and subcontracting processes.